Function

TRANSEC is a system to dry Power Transformers of all sizes. The Problem of wet Transformer is already well known. Due to moisture and oxygen, the insulation paper within the Transformer degenerates. One of the products of this chemical process is H O. While only a small part 2 of the moisture is absorbed by the Transformer oil, more than 95% of the moisture becomes diffused in the tons of insulation paper. Depending on the percentage of moisture, the aging of the Transformer increases and failures such as flashovers between the windings, treeing, and creeping discharges occur. Temperature changes of the oil during the operation even increase the risk of an outage.

Once the oil in the Transformer gets dried by TRANSEC, it dehumidifies the insulation paper and returns back again to the unit. Using this cycle effect, TRANSEC keep the insulation paper permanently dry, ensure a faultless operation and elongates the life expectancy of the Transformer significantly. Comparing to other solutions, the Transformer can be dried during its operation. There is no need to transport or switch it off.

Operational Principle

TRANSEC is an online drying sieves. The unit consists of an electrical pump, special water absorber cylinders and measuring sensors to monitor the amount of removed water. The System can either be mounted directly on a Power Transformer or can be installed next to it. Two pipes are connected to the upper and lower part of the Transformer body. After the unit is installed and switched on, the pump continuously cycles the transformer oil through the cylinders. Within the cylinders, water absorbing material removes the moisture from the oil. After this process, the oil goes through a particle filter to ensure its cleanliness before it returns back to the Transformer. An inbuilt deaerator insures, that no air will enter the tank. Every TRANSEC unit includes sample / measuring points at the inlet and outlet (to check the moisture content in the oil). An additional prefilter and a monitoring system can be added to the unit as an option.

Technical characteristics

|

CL3 |

CL1 |

||

|

in Frame |

in Cabinet |

In Frame |

|

|

Weight, kg |

220 |

350 |

90 |

|

Dimension (HxWxD), mm |

1950x705x320 |

2300x915x435 |

1950x455x320 |

|

Material |

304 grade stainless steel |

||

|

Environmental Condition |

0°C to + 90°C |

||

|

Water capacity, litre |

3 x 4 = 12 |

4 |

|

|

Transformer size |

> 10 MVA |

< 10 MVA |

|

|

Protection class of cabinet/frame |

Designed to comply with IP64 (in frame) / IP65 (in enclosure) |

||

|

Installation time, h |

5–6 (with two specialists) |

||

|

Max oil temp, C |

110° |

||

|

Pump capacity, l/hr |

90 |

||

|

Electrical supply for pump |

240V; 50Hz; 0.27kW / (120V; 60Hz – possible) |

||

|

Pipes |

Stainless steel pipes bent on site or hydraulic flexible pipes; Flange adaptors, non-return valves and bleed valve |

||

|

Modules (optional) |

Output : Analogue 0-20mA or 4-20mA for SCADA |

||

|

Temperature and Moisture probes at inlet and outlet with local LCD display |

|||

|

Monitoring for ppm and temperature. |

|||

|

IEC61850 SCADA integration via Ethernet or fibre optic |

|||

|

Type Test |

System pressurised to 3 bar for 1 hour at 110ºC (pump not running) to prove leak free |

||

|

Routine Test |

Each unit is tested pressurised to 2 bar for 30 minutes at 60ºC to prove leak free. |

||

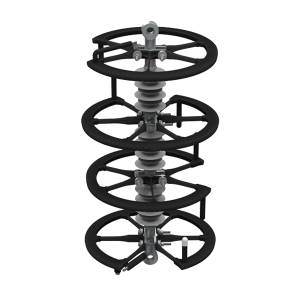

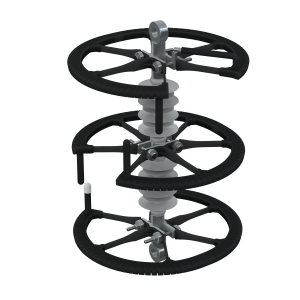

Models

CL3A• high capacity for moisture extraction (12 litre) |

CL1A• low weight, easy to move |

|

|

Optional accessories

| Monitoring

|

Prefilter

|

| Enclosure

|

Slam Shut Valve

|

Cylinder regeneration

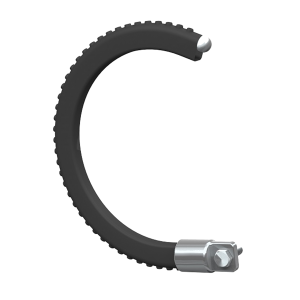

When TRANSEC is retrofitted on an existing transformer with high percentage of moisture (>2% of moisture in paper), the filter-cylinders will extract their maximum capacity within 6 to 24 months depending of moisture level at installation date, of the transformer load and temperature. The filter-cylinders will have then to be replaced and a new cycle of filtration will start. The following regenerations will happen after a longer period of filtration as the overall moisture level in the transformer has decreased.

On a new or very dry transformer (<1% of moisture in paper) the filtration time will be longer (at least a couples of years) before the filter-cylinders are saturated.

Saturated cylinders can easily be identified by using the inbuilt measuring module or by measuring manually on the in- and output of TRANSEC. If the proportion of the water in the oil remains the same, the filter needs to be changed.

The replacement of the Filter-Cylinders can be done on the installed device. Two valves, on the income and the outcome of TRANSEC need to be closed and the remained oil needs to be caught. The cylinders can directly be replaced by new types while the saturated cylinders can be shipped back to TRANSEC for the regeneration process.

This operation takes approx. 30 min per cylinder and can be done while the Transformer is running and operational.