ADVANTAGES

• Easy to install and use

• Portable, battery-operated, wireless data transfer, weatherproof

• Mirador-Tx software allows automatic configuration and 3D positioning

• Simultaneous processing of AE and PD signals

• NEW: Monitoring Feature!

APPLICATION AND OPERATION

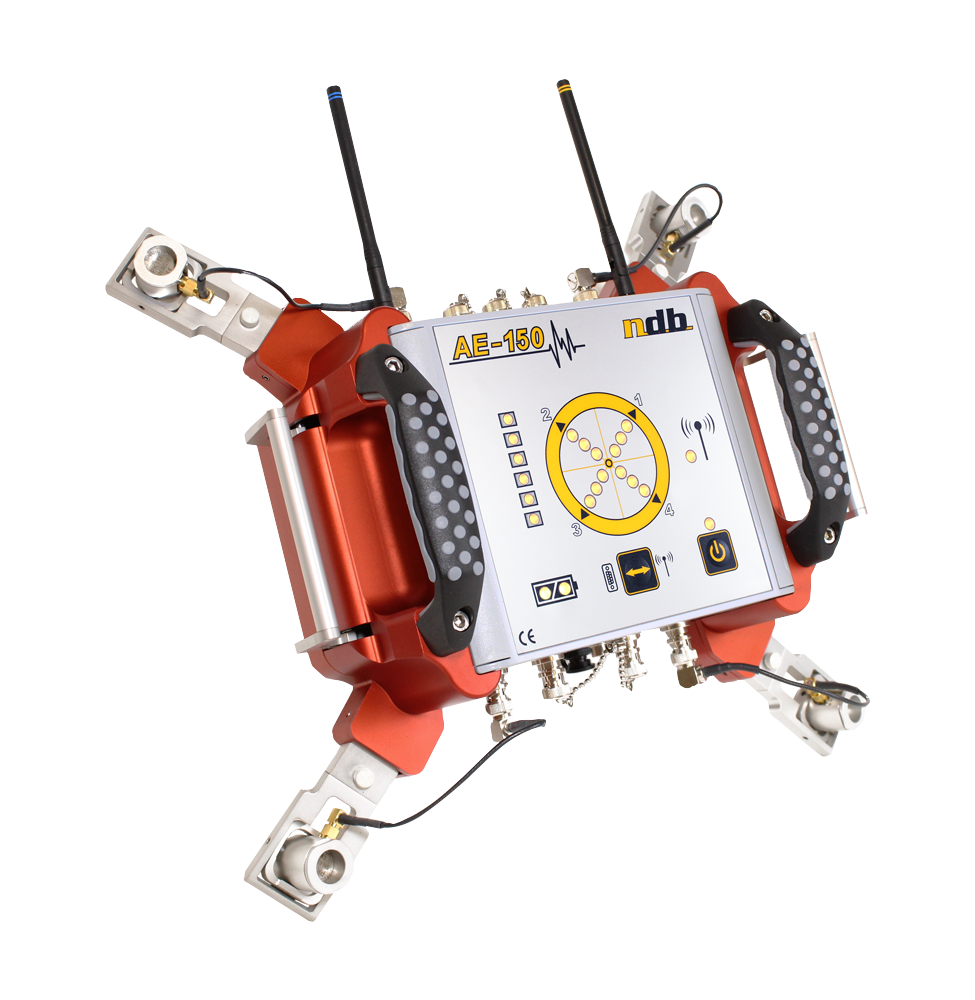

Power transformers are critical to transmission and distribution substations. In fact, losing a unit can have major financial consequences. To protect your investment, use Acoustic Emission Testing. This technique is superior to electric methods for on-site testing. The AE-150TM detects and locates Partial Discharges in power transformers by analyzing ultrasonic waves produced by electrical insulation breakdowns or high heat. The ultrasonic waves travel through the oil and strike the transformer’s tank, providing the AE-150TM the signals needed to locate the flaw. The instrument is installed on the transformer using the integrated magnetic mounting system. This features provides an easy way of moving the AE-150TM to survey the entire transformer. The remote user interface and the RF communication system allow safe operation of the unit in any outdoor conditions.

Developed in partnership with Hydro-Quebec and I.R.E.Q. laboratory, the AE-150TM brings a high level of acoustic and electrical expertise in an easy- to-use and efficient package.

ACOUSTIC AND ELECTRIC

While performing the test, all four acoustic sensors and electric sen- sor will receive a signal with from the partial discharge source. The software algorithms will make the correlation between those signals by using the arriving delays in order to draw a vector in the tank’s representation.

LOCALIZATION

After performing the test at multiple localizations on the tank, a few vectors will start to cross. This crossing section represents the partial discharge localization position.